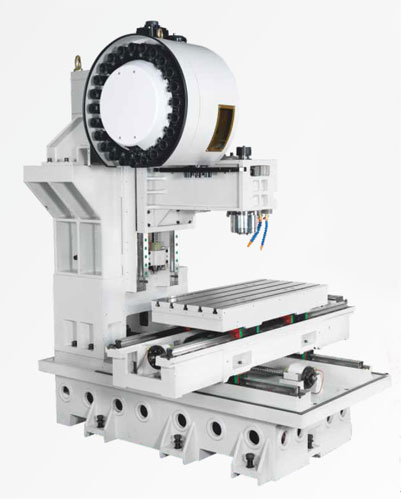

VM 1060

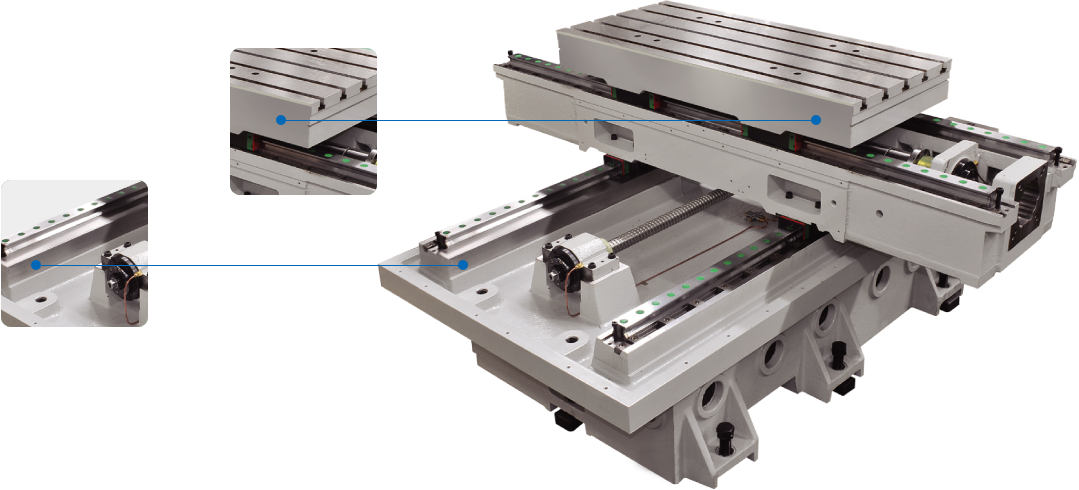

- Cross Roller Linear ways

- Rapid feed rate 36m / min

- Specifications

- Accessories

- Electronic Catlog

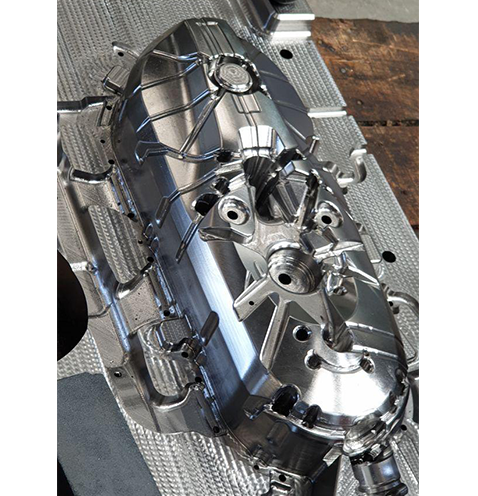

- Dynamic Cutting

- Salient Feature

| Table | ||

|---|---|---|

| X-Axis | mm | 1030 |

| Y-Axis | mm | 600 |

| Z-Axis | mm | 600 |

| Table work area (LxW) | mm | 1160 x 600 |

| Max. table load | kg | 1000 |

| T-slot dimensions | mm | 5 x 18 x 100 |

| Distance | ||

| Spindle center to column | mm | 598 |

| Spindle nose to table surface | mm | 150 - 750 |

| Rapid feed rate | ||

| X / Y / Z - axis | M/min | 36 / 36 / 32 |

| Controller | ||

| Controller | Mitsubishi / ( Fanuc / Heidenhain ) | |

| Spindle | ||

| Spindle taper | - | BT-40 |

| Spindle motor | KW | 7.5/11 (11/15) |

| Belt-drive BT-40 | rpm | 10000(12000) |

| Direct drive BT-40 (opt.) | rpm | 10000/12000/15000 |

| Belt-drive BT-50 | rpm | N/A |

| Drirect-drive BT-50 (opt.) | rpm | N/A |

| ATC | ||

| Arm type | - | |

| Miscellaneous | ||

| Power consumption | KVA | 25 |

| Pneumatic supplier | Kg/sq.cm | 6 |

| Coolant tank capacity | liter | 220 |

| Machine weight | kg | 6800 |

| Floor space (LxWxH) | mm | 2900 x 2350 x 2750 |

| Packaging size (LxWxH) | mm | |

STANDARD

- Alarm Light

- Flexible Cover

- Mistubishi M80 Controller

- Full Enclosure

- BT40 Spindle

- Rigid TappingHeat Exchanger

- Heat Exchanger

- Operating Manual

- Level Adjusting Bolt and Pads

- Rail Auto Lube System

- Remote MPG

- Transformer

OPTIONAL

- Spindle (direct type) (DDS)

- 4th / 5th Axis Roary Table Tailstock and Chuck

- Chip Conveyor / Chip Screw

- Auto Power off System

- Spindle Auto Air Blast Device

- Coolant thru Spindle

- Flood Coolant

- A.T.C (Arm Type) 24 Tools

- Spindle Oil Cooler

Kinematics VM 1060

FEATURES

SALIENT FEATURE

Mechanical Casting of VM 1060 machine

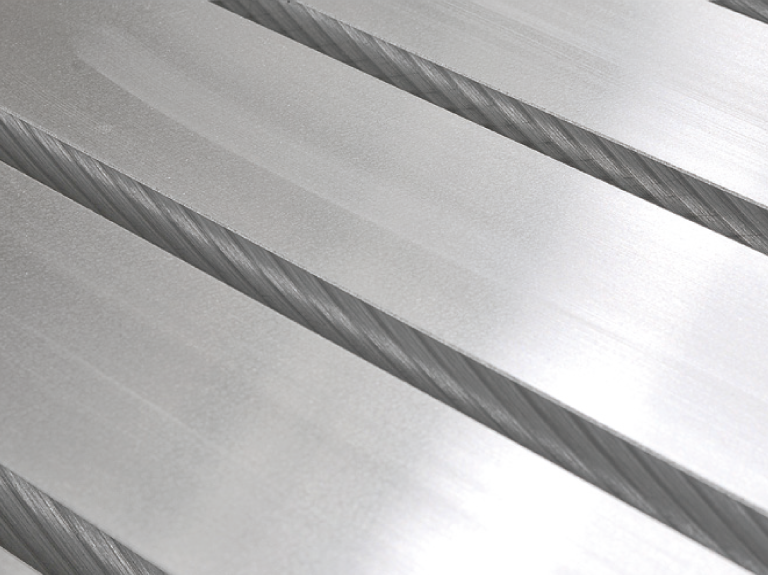

2 Roller Guideways on Y axis to provide stability and rigidity during machining.

SPINDLE CHILLER (Oil or Water)

The spindle chiller will help maintain a stable spindle temperature and will reduce the effects of thermal expansion of the spindle main shaft as well as extend the life of the spindle.

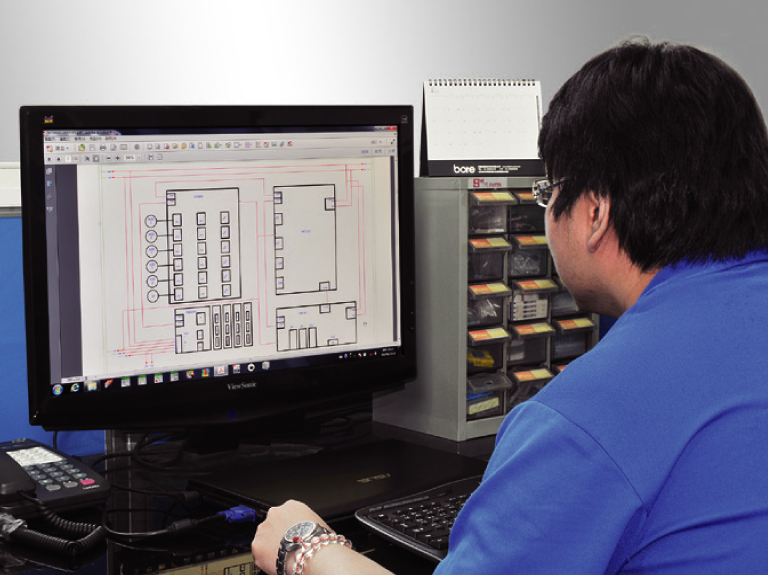

IN HOUSE CIRCUIT DESIGN

The kinematics R&D team can design both hardware and software components for the machine tools and allows for better quality control and quick response to customers requests.

T-SLOT GRINDING

Each T-Slot is ground to a H8 tolerance to provide an accurate datum surface allowing for easy and precise machine setup.

LINEAR SCALE MOUNTING SURFACE

A precision ground surface can be added to each axis to allow for easy installation of linear scales by ensuring a straight and parallel surface.